This is a preview of the detailed Kadee Logging Caboose #2 on the Perch Lake Lumber Company

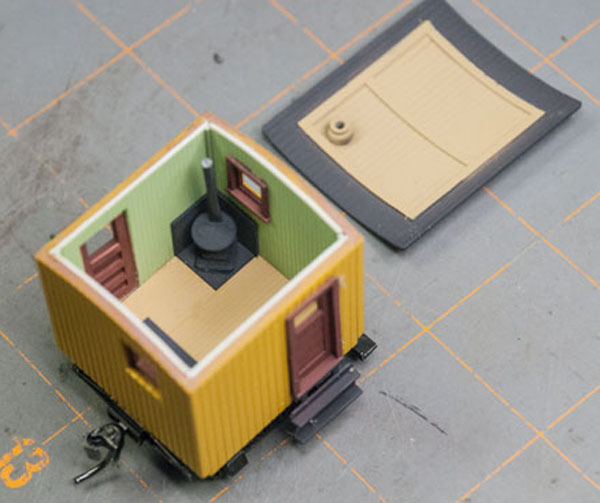

Here is the Caboose in it's first test assembly.

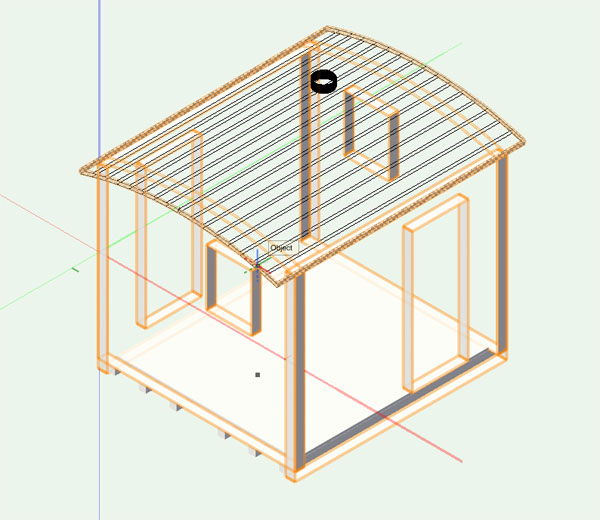

Drafting of the outside frame in 3D

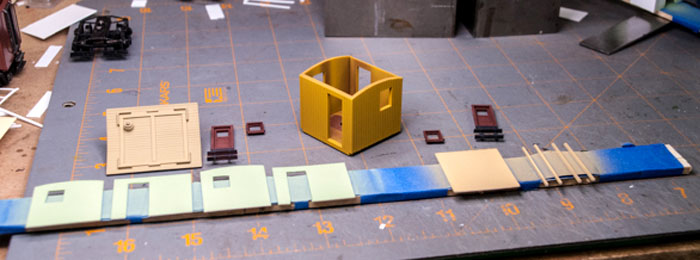

Here are some of the parts going into the model. Interior walls were cut from .020" evergreen siding and painted a light green which conforms to the interior of prototype caboose. The floor is also cut from Evergreen plastic and painted with Floquil Foundation as is the underside of the roof. Die marks in the roof were removed and extra bracing was added before airbrushing. The doors were only detailed on the outside so I added frames and 3 panels to the inside before painting. Hand rails and grab irons were paint black as were the steps. Windows and doors, inside and out were painted Boxcar Red.

The following is my current write-up for evaluation:

Kadee Logging Caboose: Perch Lake Lumber Company #2

Construction: Score of ____ out of 40

Materials Selected:

Kadee Kit

Evergreen Plastic compatible with the plastic body for the interior walls

Plastic for construction of the work bench heat shield and other attachments inside the car

Metal wire for forming coupler levers and eyes for holding the same

Plastic strips were cut and attached to the metal doors with ACC

Window Casting were matched inside with the outside castings

This model is a rebuild and super-detail of a plastic Kadee logging industrial caboose. The kit provided a body shell and frame. An interior was constructed from Evergreen Plastic to fit the 5 sided cube by careful measurement. These interior walls were airbrushed light green checked with Jim Vail for authenticity in this caboose. Windows and doors were cut into the interior and detailed for the interior view. The windows were added to the interior and .005” clear plastic was positioned into the windows. The door casting were one sided so I added interior 3 panel frames made from plastic precision cut to fit the cast doors. These parts were cemented with ACC to the casting. Doors and windows were airbrushed in Boxcar Red and Grimy Black. The roof needed to be rebuilt to fit the new interior size of the car. The roof casting were removed and new support beams were installed to allow the locking the roof to the car with the new interior size. Air hose and air line was extended thru the frame of the car. Marker lights were installed for service on the SOO Line main when in operation off the lumber feeder lines.

Score of ____ out of 40

********************************************************************

Detail: Score of ____ out of 20

Free standing wire grabs were sized, painted and installed

Cut levers were installed for the couplers

Coupler boxed were installed with details

Marker lamps were installed

Train air line and air hoses were installed

Interior walls were installed

Interior window frames were installed

Interior door detail was added

Beams in the roof were installed to replace plastic tabs and the roof was detailed Interior workbench scratch built

Potbelly stove built from parts of a kit

Tools painted and installed

Score of ____ out of 20

********************************************************************

Conformity: Score of ____ out of 25

The model is based on the Kadee Logging and Industrial 4 wheel bobber caboose used in the logging industry. Many variations of this design were used in the north woods by logging companies. This model covers the use on the Woods Lumber company and the Roddis line that moved on trackage rights of the SOO Line between the Lumber company sidings (installed by SOO Line workers and the Mills in Rhinelander or Marshfield, WI. Equipment was added to allow for air brake systems and required markers.

Score of ____ out of 25

********************************************************************

Finish and Lettering: Score of ____ out of 25

The car body was airbrushed in the Perch Lake Lumber Company standard yellow with Boxcar Red accents on the doors and windows. The under frame, along with the steps were painted grimy black and weathered with rust. The interior was painted an appropriate light green with wood floors and roof woodwork showing as natural wood. Weathering inside and out was with weathering powders and pastels, fixed with a flat finish. Various parts were accented with other colors. Lettering was typical minimum for this type of rolling stock of the time and was done with dry transferred and weathered to show a small amount of ware. The caboose is built to look rather new and well maintained but definitely used.

Score of ____ out of 25

********************************************************************

Scratch Built: Score of ____ out of 15

The model was moderately rebuilt and superdetails added to the plastic Kadee caboose model. The kit body is a 5 sided structure that casted in plastic with a cast metal under frame which extends into the body of the model. Modifications were made to the medal under frame to allow for the installation of a simulated wood floor and add the air Lines to pass brake air for main line use. The Plastic shell required careful measurement for the construction and installation of the interior walls which were scratch built from Evergreen plastic and fitted with windows and doors to match the plastic body casting. Grab irons were modified to fit the new walls and painted black. Interior construction on the roof to allow the refitting of the roof was scratch built from carefully cut scale 2 X 6 inch scale plastic boards and attached with care to the modified roof. These modifications also required the removal of casting port marks and the removal of plastic tabs that fit into the original body.

Score of ____ out of 15

********************************************************************

Here are my thoughts (not good enough for the big time Evaluation and may not make my min.)

| Total | max | % | min | % | |||||

| Construction | 40 | 30 | 75.00% | 25 | 62.50% | ||||

| Detail | 20 | 15 | 75.00% | 11 | 55.00% | ||||

| Conformity | 25 | 15 | 60.00% | 15 | 60.00% | ||||

| Finish & Lettering | 25 | 18 | 72.00% | 10 | 40.00% | ||||

| Scratch Building | 15 | 10 | 66.67% | 8 | 53.33% | ||||

| 125 | 88 | 70.40% | 69 | 55.20% |

Updated 11/03/15

Join us in the “Greatest Hobby” as a member of the TLMRC.